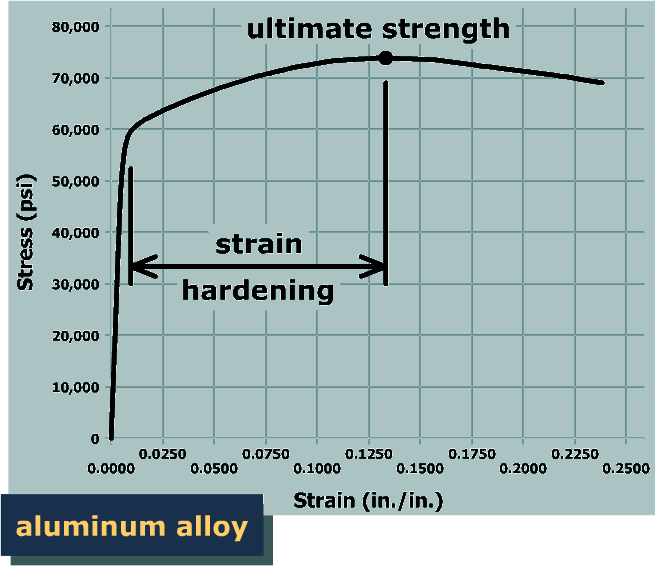

After yielding has taken place, most materials can withstand additional stress. The stress-strain curve rises continuously toward a peak stress value, which is termed the ultimate strength. The ultimate strength may also be called the tensile strength or the ultimate tensile strength (UTS). The rise in the curve is called strain hardening. The strain hardening regions for a low-carbon steel and an aluminum alloy are indicated on the stress-strain diagrams below.