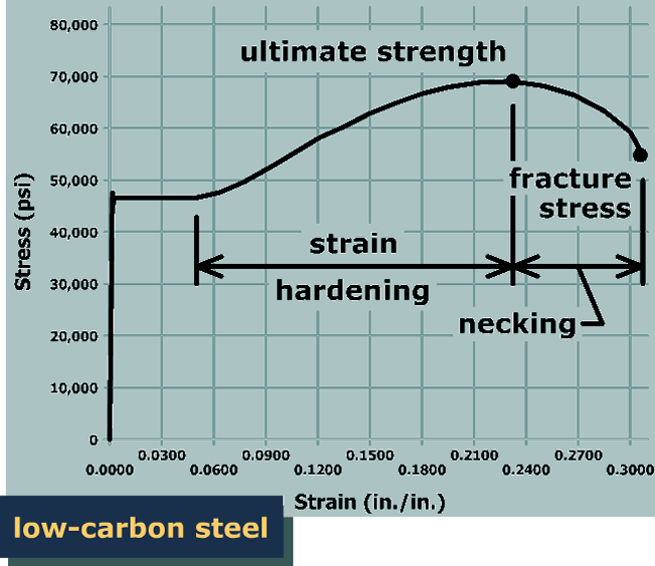

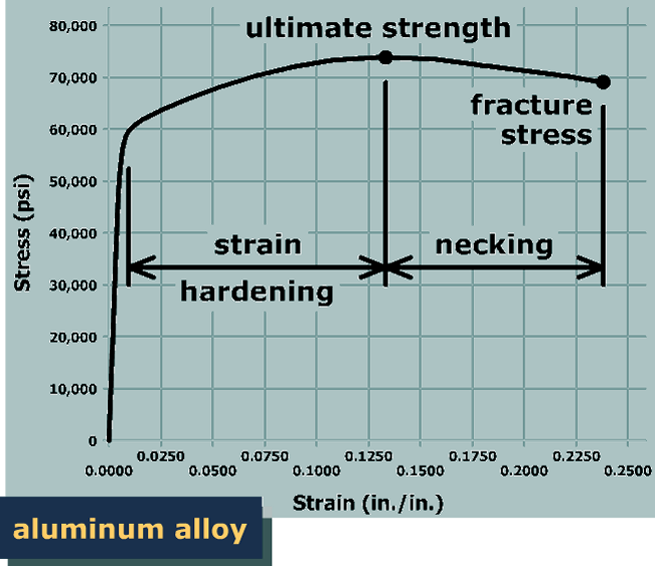

The stress at which the specimen breaks into two pieces is called the fracture stress.

Examine the relationship between the ultimate strength and the fracture stress. Doesn't it seem odd that the fracture stress is less than the ultimate strength? If the specimen didn't break at the ultimate strength, why would it break at a lower stress?