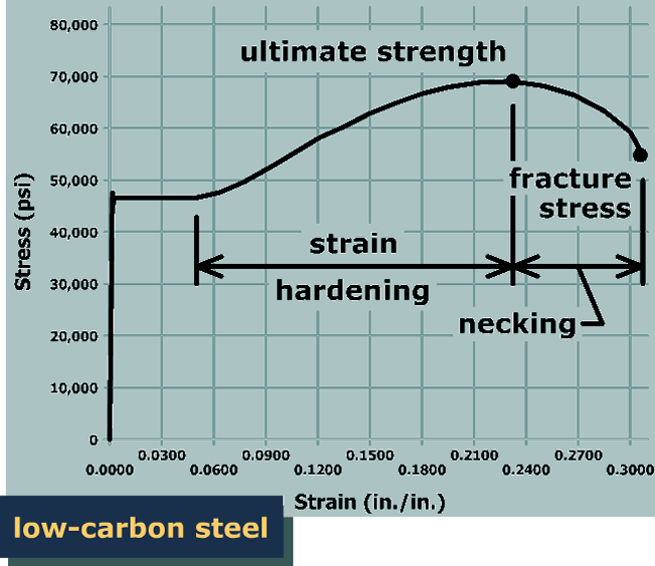

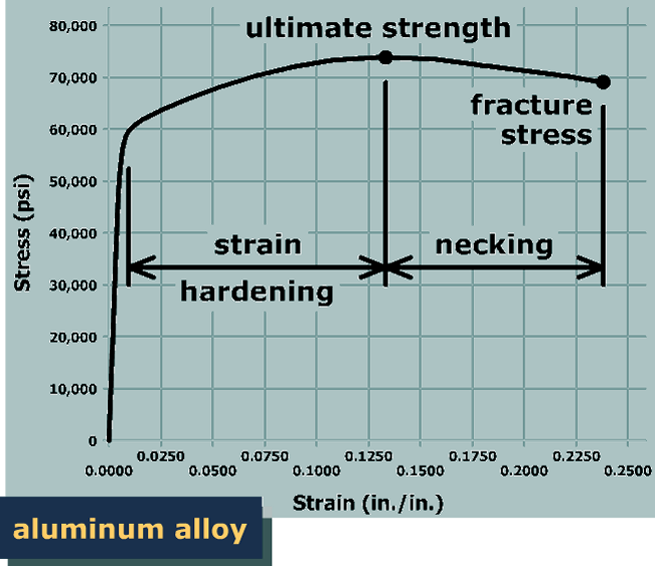

Recall that the normal stress in the specimen was computed by dividing the specimen load by the original cross-sectional area. This method of calculating stresses is known as engineering stress. Engineering stress doesn't take into account any changes in the specimen cross-sectional area during application of the load.