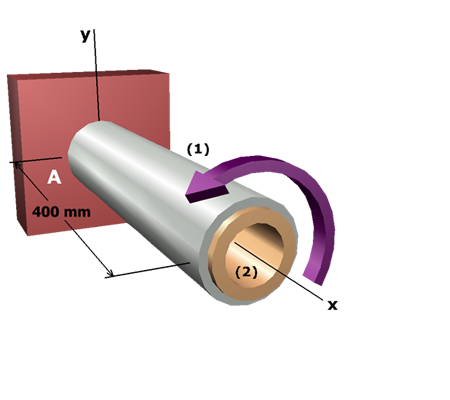

The procedure to solve this problem can be outlined as:

• Stress relationship

Expressions for shaft torques can be obtained from the elastic torsion formula. Substituting these expressions into the compatibility equation gives a relationship between the shear stresses in the shafts.

• Controlling shear stress

Using the relationship between shear stresses in the two shafts and the allowable stresses, the shaft that controls the design can be determined.

• Shaft torques

Once the shaft stresses are known, the internal torques and and the maximum external torque can be computed.