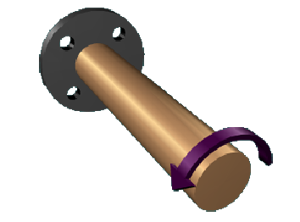

M6.1: Torsion Concepts

Concept Checkpoint

Basic torsion problems involving internal torques, shear stress, and angles of twist.

M6.2: Torsion Theory for Circular Sections

Theory

Derive elastic torsion formula and angle of twist formula.

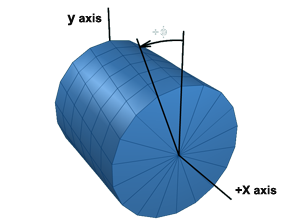

M6.3: Sign Conventions for Torsion Analysis

Theory

Sign conventions used for internal torque, shaft element twist angles, and rotation angles.

M6.4: Allowable Torque in a Pipe Shaft

Example

Given an allowable shear stress, determine the maximum torque that can be applied to a pipe shaft.

M6.5: Minimum Diameter for a Solid Shaft

Example

Determine the minimum diameter required for a solid shaft.

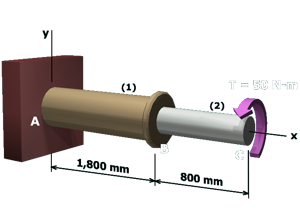

M6.6: Twisting of a Compound Torsion Member

Example

Determine minimum shaft diameter required to satisfy a twist angle limit.

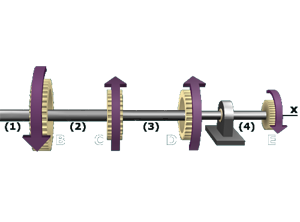

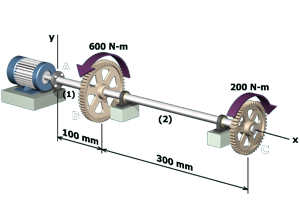

M6.7: Multiple Torques

Example

Use both the elastic torsion formula and the angle of twist formula to determine shear stresses and rotation angles.

M6.8: Maximum Torque Based on Twist Angle

Example

Based on a twist angle limit, determine the maximum torque that can be applied to a gear.

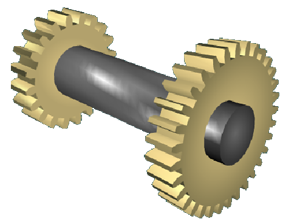

M6.9: Gear Basics

Theory | Concept checkpoints

Basic gear relationships for torque, rotation angle, rotation speed, and power transmission.

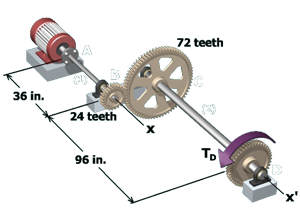

M6.10: Gear Trains: Torque and Shear Stress (Two Shafts)

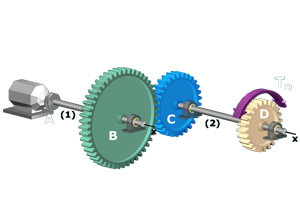

Concept checkpoints

Basic calculations involving two shafts connected by gears.

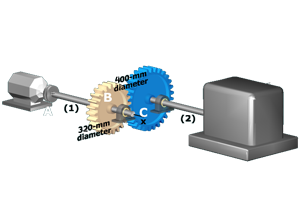

M6.11: Gear Trains: Torque and Shear Stress (Three Shafts)

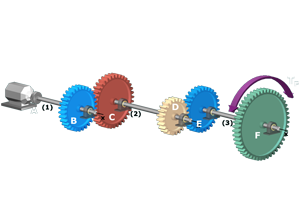

Concept checkpoints

Basic calculations involving three shafts connected by gears.

M6.12: Gear Trains: Angles of Twist

Concept checkpoints

Basic twist and rotation angle calculations involving two shafts connected by gears.

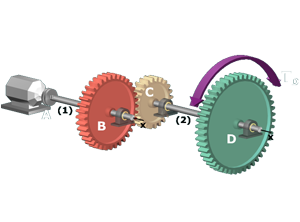

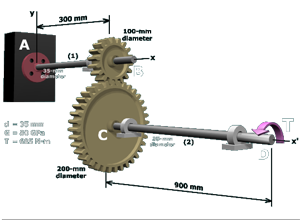

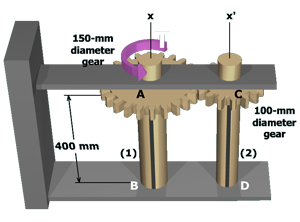

M6.13: Two Shafts Connected by Gears

Example

Determine the shear stress in each shaft and the rotation angle at the free end.

M6.14: Gear Trains: Power Transmission (Two Shafts)

Concept checkpoints

Basic calculations involving power transmission in two shafts connected by gears.

M6.15: Gear Trains: Power Transmission (Three Shafts)

Concept checkpoints

Basic calculations involving power transmission in three shafts connected by gears.

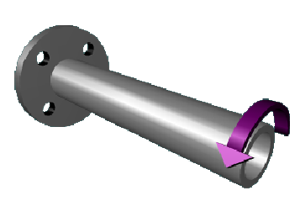

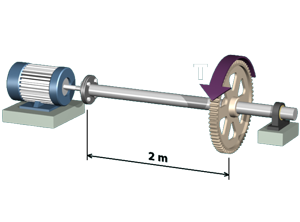

M6.16: Determine Power Transmitted by a Shaft

Example

Determine the maximum power that can be transmitted by a shaft within limits on shear stress and twist angle.

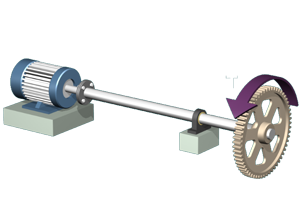

M6.17: Shaft Diameter Based on Power

Example

Determine the minimum diameter required to transmit a specified power.

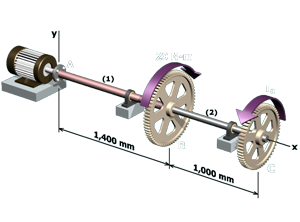

M6.18: Motor-driven Shafts

Example

Determine the maximum shear stress in two gear-connected shafts. Also, determine the rotation angle of a gear.

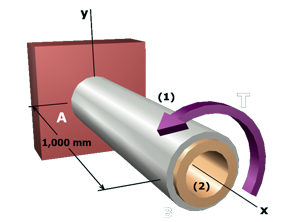

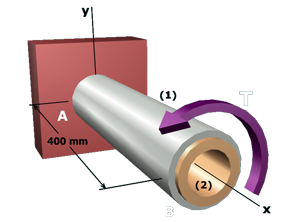

M6.19: Shear Stresses in Coaxial Shafts

Example | Try one

Determine internal torques and shear stresses, and shaft rotation angle in two coaxial shafts.

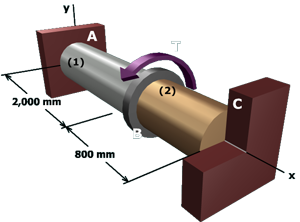

M6.20: Shear Stresses in End-to-end Shafts

Example | Try one

Determine internal torques, shear stresses, and rotation angles for a compound torsion member.

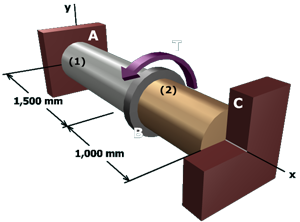

M6.21: Maximum Torque for Composite Shaft

Example | Try one

Determine the maximum torque that can be applied to a compound torsion member given allowable shear stresses.

M6.22: Maximum Torque Applied to Coaxial Shaft

Example

Given allowable shear stresses for two coaxial shafts, determine the maximum torque that can be applied to the assembly.

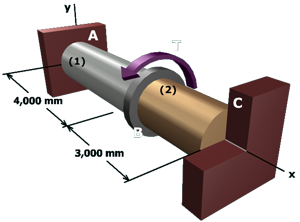

M6.23: Shafts With Specified Rotation Angle

Example

Determine the maximum torque that can be applied to a compound torsion member based on a rotation angle limit.

M6.24: Indeterminate Gear Mechanism

Example

Determine the shear stresses produced in two shafts connected by gears.